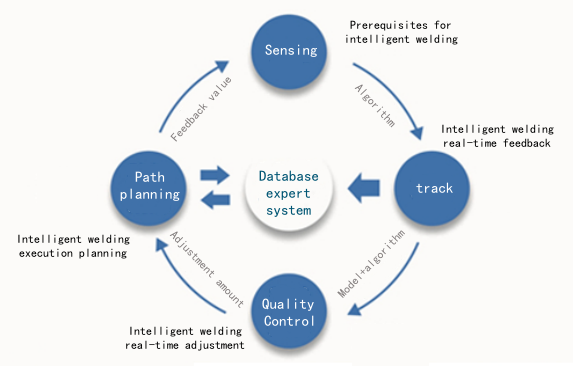

Self-organization - according to the feedback of expert system and visual system, realize the planning of welding track and parameters.

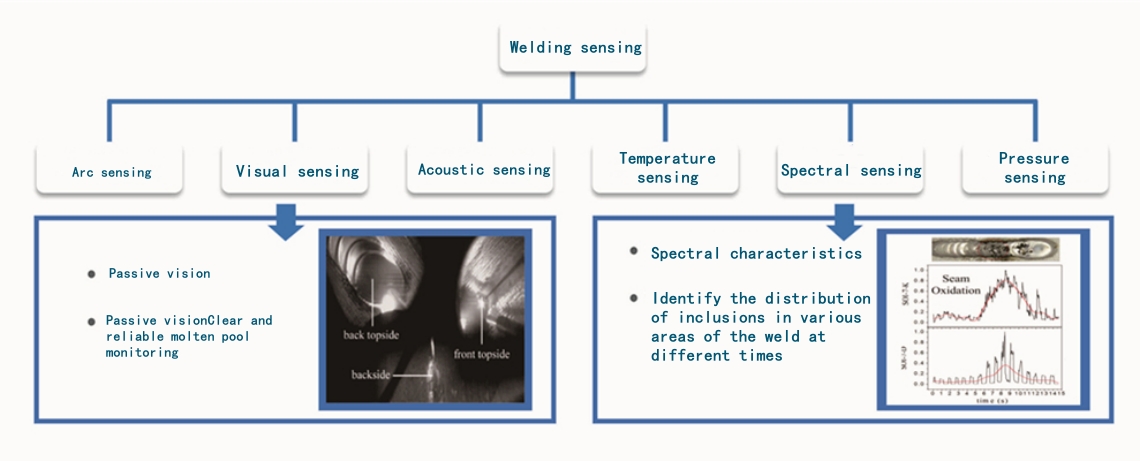

Self-sensing - use arc sensing, visual sensing and spectral sensing technology to extract various types of parameter information in the welding process.

Self-adaptation - according to fuzzy control, expert control and other algorithms, combined with welding model, realize the adaptation of welding trajectory and parameters.

Self-adjustment - based on the feedback information of welding sensor, real-time adjustment of welding parameters and trajectory can achieve reliable welding.